Double disc coupling is a flexible coupling. Often use for servo motor,stepping motor design.We are double flex disc coupling manufacturer in CHINA.

Double disc coupling is a kind of high performance flexible coupling. This coupling with strong metal components, no need to moisten oil, compact structure. High strength, long service life, no rotation gap, not affected by temperature and oil.

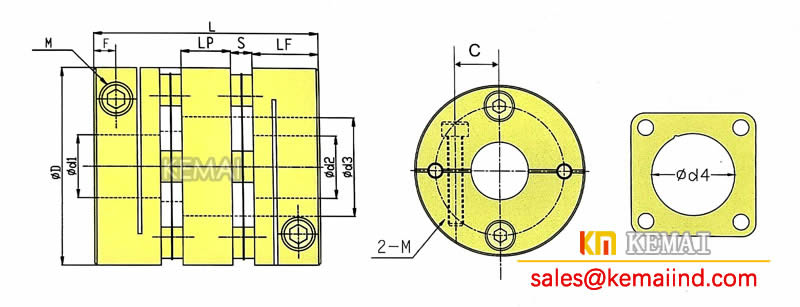

Double Disc Coupling

A2C Series

A2C-Outside diameter X Total length – d1 bore X d2 bore

Example: A2C-56X65-16X18

A: Aluminum;

2: Double Disc;

C: Clamping Type;

56: Outside diameter;

65: Total length;

16: d1 bore diameter;

18: d2 bore diameter;

Please note:If you need this coupling size is big,please check disk coupling.

| Model | d1,d2,Bore | ΦD | L | LF | LP | d3 | Φd4 | S | F | C | M | Wrench Torque

(N.M) |

| A2C-19×27 | 3,4,5,6, 6.35 ,7,8,10 | Φ19 | 27 | 9 | 5 | Φ9 | 8.4 | 2 | 3.3 | 6 | 2-M2.5×10 | 1 |

| A2C-26×33 | 5,6, 6.35 ,7,8,9, 9.525 ,10,11,12, 12.7 ,14 | Φ26 | 33 | 10.65 | 6.6 | Φ12 | 10.5 | 2.7 | 3.9 | 8.58 | 2-M2.5×10 | 1 |

| A2C-26×35 | 5,6, 6.35 ,7,8,9, 9.525 ,10,11,12, 12.7 ,14 | Φ26 | 35 | 11.65 | 6.6 | Φ12 | 10.5 | 2.7 | 3.9 | 8.58 | 2-M3x12 | 1.5 |

| A2C-32×41 | 6, 6.35 ,7,8,9, 9.525 ,10,11,12, 12.7 ,14,15 | Φ32 | 41 | 125.25 | 8.7 | Φ15 | 14.5 | 3.9 | 3.85 | 11 | 2-M3x12 | 1.5 |

| A2C-34×41 | 6, 6.35 ,7,8,9, 9.525 ,10,11,12, 12.7 ,14,15 | Φ34 | 41 | 125.25 | 8.7 | Φ15 | 14.5 | 3.9 | 3.85 | 11.25 | 2-M3x12 | 1.5 |

| A2C-34×45 | 6, 6.35 ,7,8,9, 9.525 ,10,11,12, 12.7 ,14,15 | Φ34 | 45 | 14.25 | 8.7 | Φ16 | 14.5 | 3.9 | 4.85 | 11.25 | 2-M4x14 | 2.5 |

| A2C-39×50 | 8,9, 9.525 ,10,11,12, 12.7 ,14,15,16,18,19 | Φ39 | 50 | 15.5 | 11.5 | Φ19 | 17 | 3.6 | 5.1 | 13.1 | 2-M4x18 | 2.5 |

| A2C-44×50 | 8,9, 9.525 ,10,11,12, 12.7 ,14,15,16,18,19,20,22 | Φ44 | 50 | 15.5 | 11.5 | Φ21 | 20.5 | 3.6 | 5.1 | 15.5 | 2-M4x20 | 2.5 |

| A2C-56×65 | 12,14,15,16,18,19,20,22,24,25 | Φ56 | 65 | 19.75 | 13.5 | Φ25 | 26 | 5.8 | 6.4 | 19.5 | 2-M5x25 | 7 |

| A2C-68×76 | 15,16,19,20,22,24,25,28,30,35 | Φ68 | 76 | 23.35 | 15.7 | Φ35 | 31 | 7 | 7.7 | 23.5 | 2-M6x35 | 12 |

| A2C-82×99 | 22,24,,28,30,35,38,40 | Φ82 | 99 | 30 | 22 | Φ42 | 41 | 8.7 | 9.7 | 28 | 2-M8x35 | 20 |

| Model | Rated torque

(N·M)

|

Maximum

Torque (N·M) |

Allow Radial direction

(mm) |

Allow angle

( °)

|

Allow Axis

(mm) |

Maximum speed

Rmp |

Static torsional

Stiffness (N·M/rad) |

Moment of

Inertia (kg·M2) |

Bushings

Material |

Flexible

colloidal material |

Surface

treatment |

Weigh

g |

| A2C-19×27 | 2 | 4 | 0.12 | 1.5 | ±0.18 | 10000 | 460 | 9.1×10-7 | Hing-strength

aluminum alloy |

SUS | Oxidation

treatment |

14.6 |

| A2C-26×33 | 3.5 | 7 | 0.15 | 1.5 | ±0.3 | 10000 | 820 | 9.0×10-7 | 35 | |||

| A2C-26×35 | 3.5 | 7 | 0.15 | 1.5 | ±0.3 | 10000 | 1860 | 3.0×10-6 | 37 | |||

| A2C-32×41 | 8 | 16 | 0.17 | 1.5 | ±0.36 | 10000 | 1750 | 1.0×10-5 | 67 | |||

| A2C-34×41 | 8 | 16 | 0.17 | 1.5 | ±0.36 | 10000 | 1860 | 1.05×10-5 | 72 | |||

| A2C-34×45 | 8 | 16 | 0.17 | 1.5 | ±0.36 | 10000 | 1860 | 1.1×10-5 | 77 | |||

| A2C-39×50 | 15 | 30 | 0.22 | 1.5 | ±0.45 | 10000 | 2860 | 3.0×10-5 | 118 | |||

| A2C-44×50 | 18 | 36 | 0.22 | 1.5 | ±0.54 | 10000 | 3300 | 3.8×10-5 | 144 | |||

| A2C-56×65 | 30 | 60 | 0.27 | 1.5 | ±0.72 | 10000 | 9480 | 1.6×10-4 | 318 | |||

| A2C-68×76 | 60 | 120 | 0.31 | 1.5 | ±0.8 | 10000 | 19000 | 2.0×10-4 | 492 | |||

| A2C-82×99 | 100 | 200 | 0.35 | 1.5 | ±0.8 | 10000 | 28450 | 2.5×10-4 | 1013 |