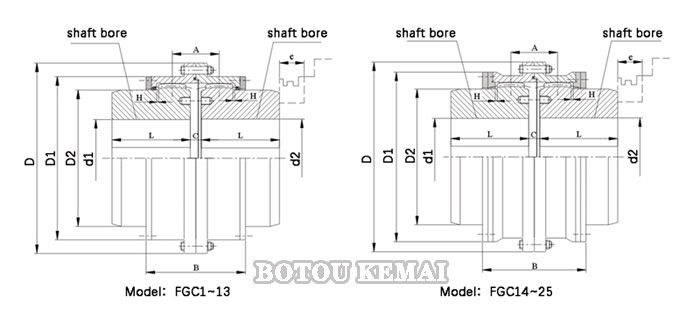

Full gear coupling model:FCG 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25.

1: Gear gap is relatively large, allowing a larger angular displacement.Improve torque transfer and prolong service life.

2. Radial, axial and angular compensation capabilities.

3. Compact structure, high transmission efficiency and low noise.

4: Use for low speed and heavy load environment.For example: mining equipment, chemical industry, general machinery and so on.

FGC10- bore diameter X bore length – bore diameter X bore length (mm)

FGC10-100X212-120X200

FGC:Full Gear Coupling

10: The size of the code

one side: bore diameter 100mm ; bore length 212mm

other side: bore diameter 120mm ; bore length 200mm

| Model | Nominal torque (KN. m) |

Allowable speed (rpm) |

bore diameter | Bore length L(mm) | Size (mm) | Moment of inertia (Kg. m*2) |

lubricating grease (ml) |

Weight (kg) |

|||||||

| d1 d2 | Y

J1 Z1 |

D | D1 | D2 | C | H | A | B | e | ||||||

| FGC1 | 0.4 | 4000 | 16~35 | 38~82 | 103 | 71 | 50 | 8 | 2 | 36 | 76 | 38 | 0.00375 | 51 | 5.1 |

| FGC2 | 0.71 | 4000 | 20~45 | 38~112 | 115 | 83 | 60 | 8 | 2 | 42 | 88 | 42 | 0.00575 | 70 | 6.2 |

| FGC3 | 1.12 | 4000 | 22~56 | 38~112 | 127 | 95 | 75 | 8 | 2 | 44 | 90 | 42 | 0.00675 | 68 | 8.6 |

| FGC4 | 1.8 | 4000 | 38~65 | 60~142 | 149 | 116 | 90 | 8 | 2 | 49 | 98 | 42 | 0.0245 | 87 | 14.5 |

| FGC5 | 3.15 | 4000 | 40~56 | 84~142 | 167 | 134 | 105 | 10 | 2.5 | 55 | 108 | 42 | 0.0433 | 125 | 19.6 |

| FGC6 | 5 | 4000 | 45~90 | 84~172 | 187 | 153 | 125 | 10 | 2.5 | 56 | 110 | 42 | 0.0848 | 148 | 31.2 |

| FGC7 | 7.1 | 3750 | 50~105 | 84~212 | 204 | 170 | 140 | 10 | 2.5 | 60 | 118 | 42 | 0.0378 | 175 | 47.5 |

| FGC8 | 10 | 3300 | 55~115 | 84~212 | 230 | 186 | 155 | 12 | 3 | 67 | 142 | 147 | 0.075 | 268 | 60.2 |

| FGC9 | 16 | 3000 | 60~135 | 107~252 | 256 | 212 | 180 | 12 | 3 | 69 | 146 | 47 | 0.151 | 310 | 95.8 |

| FGC10 | 22.4 | 2650 | 65~150 | 107~252 | 287 | 239 | 200 | 14 | 3.5 | 78 | 164 | 47 | 0.241 | 472 | 119 |

| FGC11 | 35.5 | 2350 | 70~175 | 107~302 | 352 | 276 | 235 | 14 | 3.5 | 81 | 170 | 47 | 1.588 | 550 | 189 |

| FGC12 | 50 | 2100 | 75~200 | 107~352 | 362 | 313 | 270 | 16 | 4 | 89 | 190 | 49 | 3.055 | 695 | 285 |

| FGC13 | 71 | 1850 | 150~225 | 202~352 | 412 | 350 | 300 | 18 | 4.5 | 98 | 208 | 49 | 4.918 | 1019 | 360 |

| FGC14 | 112 | 1650 | 170~250 | 242~410 | 462 | 420 | 335 | 22 | 5.5 | 172 | 296 | 63 | 9.725 | 3900 | 544 |

| FGC15 | 180 | 1500 | 190~285 | 282~470 | 512 | 470 | 380 | 22 | 5.5 | 182 | 316 | 63 | 17.45 | 4000 | 786 |

| FGC16 | 250 | 1300 | 220~320 | 282~470 | 580 | 522 | 430 | 28 | 7 | 198 | 354 | 67 | 29.1 | 4500 | 1027 |

| FGC17 | 355 | 1200 | 250~365 | 330~550 | 644 | 582 | 490 | 28 | 7 | 209 | 364 | 67 | 53.725 | 4900 | 1532 |

| FGC18 | 500 | 1050 | 280~400 | 380~650 | 726 | 658 | 540 | 28 | 8 | 222 | 430 | 75 | 99.5 | 7000 | 2278 |

| FGC19 | 710 | 950 | 300~460 | 380~650 | 818 | 748 | 630 | 32 | 8 | 232 | 440 | 75 | 175.5 | 8900 | 3026 |

| FGC20 | 1000 | 800 | 360~540 | 450~800 | 928 | 838 | 720 | 32 | 10.5 | 247 | 470 | 75 | 360.75 | 11000 | 4430 |

| FGC21 | 1400 | 750 | 400~600 | 540~800 | 1022 | 928 | 810 | 40 | 11.5 | 255 | 490 | 75 | 561.5 | 13000 | 6152 |

| FGC22 | 1800 | 650 | 450~680 | 540~900 | 1134 | 1036 | 915 | 40 | 13 | 262 | 510 | 75 | 904.75 | 16000 | 7738 |

| FGC23 | 2500 | 600 | 530~770 | 680~900 | 1282 | 1178 | 1030 | 50 | 14.5 | 299 | 580 | 80 | 1725 | 28000 | 11553 |

| FGC24 | 3550 | 550 | 560~850 | 680~1000 | 1428 | 1322 | 1175 | 50 | 16.5 | 317 | 610 | 80 | 3131.75 | 33000 | 16615 |

| FGC25 | 5000 | 460 | 670~1040 | 780~1100 | 1644 | 1538 | 1390 | 50 | 19 | 325 | 620 | 80 | 7198.25 | 43000 | 27797 |